🎓 LIN systems: A clever solution

LIN is a brilliant evolution and addition to CAN systems. Each switch or lever is in itself a small ECU called a “Sub Hardware”. Each sub hardware unit is connected to the main ECU in its area or zone by means of LIN.

LIN connections comprise of 3 wires: a positive, a negative and a “signal”. The negative will be spliced with many other negative wires in the area and generally fixed to the body or chassis of the vehicle.

The positives will be spliced together in groups, where each group targets a specific zone of the vehicle, depending on where the parent ECU is located. This allows for less wires and more importantly for technicians, allows the ECU, when needed, to isolate a faulty area and register a DTC relating to the power supply group of that zone. This is a great feature as you can concentrate on an area, for example the right side of the cab, instead of dismantling the entire interior.

The “Signal” wire from a specific switch or switch panel will be connected to a specific pin on the main ECU. The main ECU interprets the information received on that line and activates the requested function.

LIN incorporation is fantastic, as many functions can be controlled by only the 3 wires. Take your door panel switch that contains buttons for the door lock, the windows front left front right rear left rear right, mirrors left and right, kiddy lock etc etc. That’s a lot of functions and as such a lot of wires would be needed.

Apart from fewer wires and localised fault tracing, LIN systems are expansion ready. Most functions are included in the standard software loaded onto the parent ECU and to activate a new function is achieved by simply adding a specific switch. The switch communicates with the ECU when the ignition is turned on for the first time after being fitted and the ECU activates the function.

Instead, we use LIN. The main ECU, in this case the driver door ECU (module) receives a specific signal from the door switch panel and sends the information out along CAN to the “Slave” ECU, for example the passenger door ECU (module). The passenger door ECU then sends out the positive or negative, whichever is needed, to the required mechanism. Pretty cool 😉. LIN simplifies fault tracing enormously, but….. there’s always a but…. This is where having test parts on hand is invaluable to efficient fault diagnosis (more on this later).

👯♂️ Grouping ECUs: Diagnostics made easy

To elaborate on the paragraph above, LIN systems have a lot of ECU’s / Modules in the vehicle. Importantly, understanding how these units are grouped together makes diagnostics manageable. Because we have ISO standards, manufacturers should use the same protocols, therefore networks (groups of modules) should be relatively similar from vehicle to vehicle, although most likely given different names. For example, in Volvo Trucks you have the “Security Subnet” whereas Mercedes may call the same group the “Antitheft Network”… please don’t quote me on that…. I’m a Volvo specialist and only using it as an example. The point is that the Security (Volvo) and the Antitheft (Mercedes) will comprise of the same group of components which again will have different names within the networks. TomAto Tomatoe, PotAto, Potatoe… Same thing different words😉

🎓 The evolution of vehicle electronics

The main purpose of this section is to give you a basic idea of the different systems and help you understand that CAN and LIN are only refinements once again of the Simple Light Circuit from earlier. Can you imagine for each new item fitted to a vehicle a new set of wires, fuses and relays needed to be added, in modern vehicles there would be nowhere to sit. The use of electronics, CAN and LIN, allows the manufacturer to essentially build one system for all their models and only add or remove components and tweak some software depending on the requested vehicle specification. In LIN variants, the parent ECU’s are factory programmed to control every additional feature we want to add. By simply adding a plug and play switch and component, the parent ECU recognizes its addition and the function works without the need for software updates. In most instances, add on wiring connections are already in place and all that is needed to complete the add on function a short wiring harness and the component itself.

As we continue through the sections you will learn to understand wiring diagrams and in so doing build the necessary skills to work out which ECU’s are part of which group, which are the parent and which are the slaves. Remember, we will be covering both CAN only systems and CAN with LIN systems. I reiterate at this point, each is only an improvement of the last not a complete redesign. Keep in mind the simple circuit from Part 6 and how these systems are only an evolved version of that.

💡 CAN and LIN: Fewer wires, more control

With CAN and LIN, the electronics or software aspect is somewhat complicated, however, vehicle electrical systems themselves have been significantly simplified, requiring fewer wires. All that’s required is power and network wires between ECUs, with short wires running from the ECU to the components it controls. ECUs are placed near the components they manage, such as a “Rear Control Unit” for the back of the vehicle or a “Cab Module” for the interior. This makes fault tracing easier because you’re only working within smaller areas instead of tracing wires across the whole vehicle.

Diagnostic Trouble Codes (DTCs) play a big part here. They help narrow down the issue, whether it’s an open circuit, a short to lower or higher voltage, mechanical system failure etc. Don’t stress, later in the series, we’ll break down DTCs and what they mean. For now, remember that a diagnostic laptop will give you the DTC and some info, but you need to know what it means before diving into troubleshooting. What’s the point of ripping apart a wiring loom if the DTC says the component is faulty? Misdiagnosing is a waste of time and money – something you want to avoid.

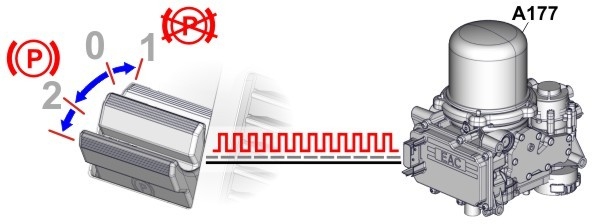

⚒ Pre LIN

In older systems, pre LIN, the switches and levers in the vehicle typically share a single common negative (ground) or positive wire. The design of the ECU dictates which signal is required from the switch. When a switch or lever is activated, it sends a signal to a specific pin on the ECU. The ECU interprets the signal received and activates the intended function. When the ignition is turned on, all functions controlled by the ECU are ready to go instantaneously upon receiving a signal form the respective switch or lever. The output side of the ECU is short circuit protected within each individual IC and the need for a fuse per light and accessory has been negated. When the IC detects a short circuit, the ECU enters protection mode. Once the fault has been repaired, the ECU comes out of protection mode and the light or accessory will automatically start working again without having to replace any fuses. The positive supply wire to the ECU is fuse protected in case of short circuit.

An advantage of this system is that there aren’t as many positive wires running under the dash and therefore the risk of short circuits is minimized, however should one arise, the fuse would pop. On the flip side, if a “negative” signal wire short circuited to ground, the ECU would receive an unwanted request to activate a function. Although there is no danger to the vehicle electrical or electronic system in this scenario, it could be quite unpleasant for oncoming traffic when your bright lights (high beams) activate spontaneously without your permission.