🎓 A quick recap

In Part 6, we covered the basics of electrical systems. This article will help explain how these systems have evolved, with a particular focus on how Electronic Control Units (ECUs) have replaced traditional fuses, relays, wiring and commands in modern vehicles. Everything from this point onwards builds on that foundation.

We started with a simple circuit that, if left connected, would drain the battery. We improved the system by adding a control switch and protection in the form of a fuse. Next, we expanded the circuit by adding a relay for the spotlights. Throughout this process, the basic wiring remained unchanged, we simply refined it. With the control switch, we could turn the light on and off without disconnecting the battery. The fuse protected the system in case of a short circuit, and the relay allowed us to supply more current by drawing power directly from the battery without overloading the light circuit.

💻 Enter the ECU

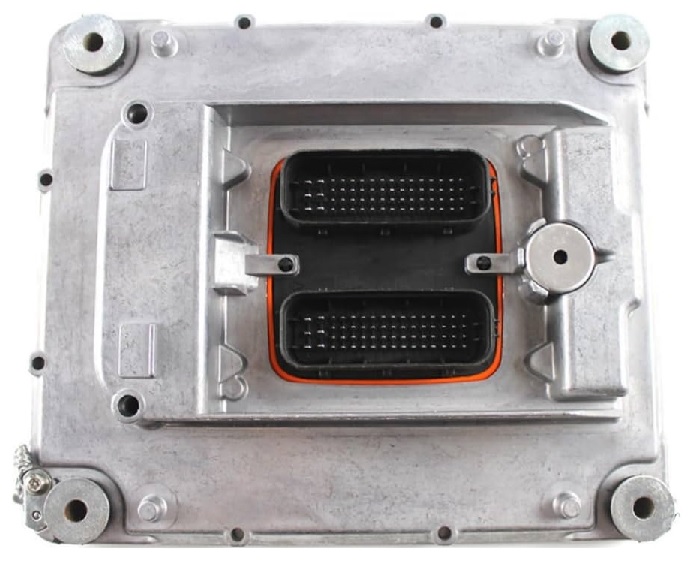

With the introduction of ECUs, vehicles now have fewer fuses, relays, and wires, resulting in a more efficient electrical system. Think of the ECU as a programmable electrical distribution center. It receives, decodes, and processes information, then sends it out to the relevant components. The ECU acts as the central hub in the system, functioning as both an INPUT and OUTPUT unit. It receives signals (inputs) and sends instructions (outputs). These inputs and outputs can be adjusted or set according to the intended use. Later in the V4 (TEA2+) CAN architecture article you will see terms such as CIOM, HMIIOM, RCIOM, FCIOM and CCIOM. All of these have “IO” in there acronyms as that’s what they are, IN / OUT modules – now for those who have jumped to that section and don’ know this, will be google searching their butts off for what IO stand for – Kudos to you sticking around here ✋🏻

An ECU in very simple terms is a compact circuit board that contains a variety of small components such as resistors, capacitors, transistors, and MOSFETs. Integrated Circuits (ICs) are components that combine multiple functions into a single small unit. ICs replace fuses, relays, and switches by performing all of these roles within one component. However, they still need to be activated somehow, which is why levers and switches remain in vehicles – unless voice activated like Kitt 🚀

The role of these switches and levers has also changed over time. In older electrical systems, they were used to directly activate vehicle functions through bulky fuse and relay boxes. In modern vehicles with ECUs, the switches and levers now only send signals to the ECU, which processes the inputs. The fuse boxes are also smaller now because they only need to provide protected power to the ECU and other standalone accessories.

It’s important to recognise that the ECU is only a box full of fancy fuses and relays. The basic operation of the vehicle’s electrical circuits remains the same as the simple light circuit we discussed earlier, where each light or component requires a positive and negative to work. It is only the delivery of the positive and negative that has changed. Much like how a carburetor was replaced with a throttle body and injectors in modern engines, fuses and relays have been replaced by ECUs, improving efficiency and reliability.

However, ECU’s as described above did not just appear out of nowhere. The first ECU’s were engine ECU’s when fuel injection made its grand appearance. Over the years we saw subtle changes in ignition systems with the phasing out of points and condensor distributors to the more favored electronic distributor. Then came the introduction of fuel injection. This was the first significant change the automotive industry had seen in many many years and it was a revelation.

For proper fuel injection functionality, an ECU (Electronic Control Unit) or EMS (Engine Management System) is essential. The advent of the ECU also led to the removal of the traditional distributor, which was replaced by a coil pack and HT leads. As time has passed, multi output coil packs with HT leads have been replaced with individual coil packs mounted directly to the spark plugs. This shift has resulted in a more compact, reliable design, eliminating the need for mechanical components that could fail. As a result, the system became not only more dependable but also more cost-effective.

With sensors fitted strategically around the engine which send precise information such as engine position (generally in reference to number 1 cylinder TDC), throttle position (how open the butterfly valve is in the throttle body) and air flow (anywhere on the intake side), ECU’s can be fine tuned for a variety of applications, such as fuel economy, huge power and torque or simply governing the engine speed limits.

Despite the change in technology, the end goal remains the same, to ensure the engine runs, idles, and accelerates smoothly. The ECU now replaces components like the accelerator cable, carburetor, and distributor. It directs the injectors and coil pack, determining when to inject fuel and fire the spark, based on data gathered from various sensors.

The evolution and improvements of electronics over the past 20 years has seen exponential expansion and refinements of ECU’s in modern vehicles and as such more mechanical processes are being replaced by electronics. Nowadays there are ECU’s for everything, even the switches and levers are little ECU’s in themselves…. Spoiler alert… LIN

📦 Let’s wrap up

It’s important to remember the role of the ECU. It has only replaced traditional mechanical control systems with precise electronic commands, taking over the functions once managed by mechanical components, they have not reinvented anything! Breaking down the electrical systems into individual circuits, understanding how sensors and components communicate with the ECU and applying the logic of a simple light circuit, as discussed in Part 6, we can gain a better understanding of even the most complex systems today.