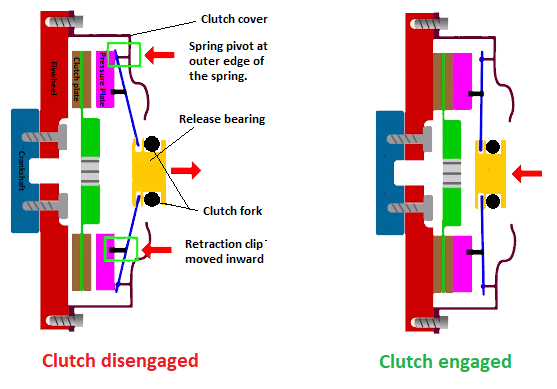

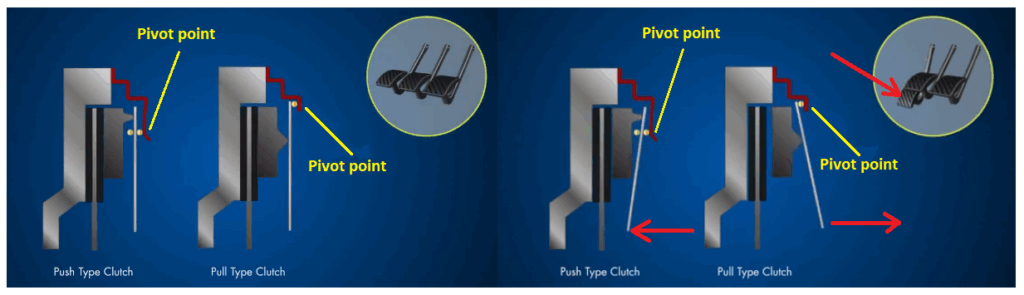

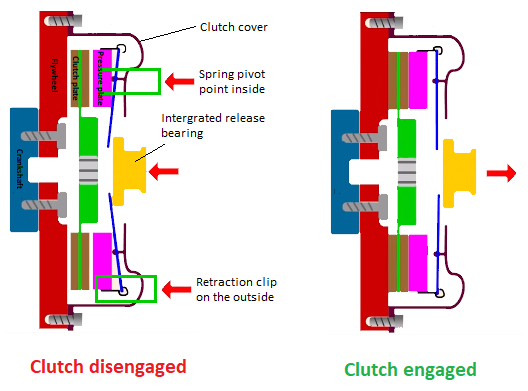

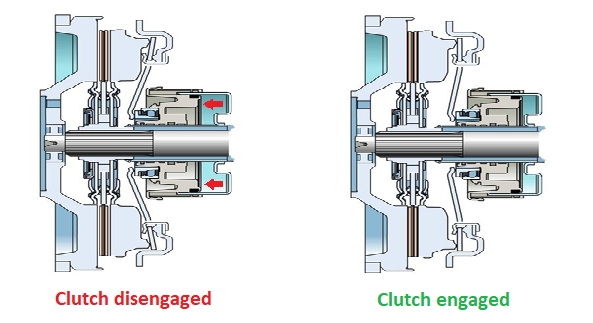

The design difference between the two clutch types is minimal. The primary distinction lies in the location of the pivot points on the clutch cover and the retraction points of the fingers and pressure plate, as illustrated in the image below.

Push type clutch

In push-type clutches, the pressure plate fingers exhibit a slightly convex shape when secured to the flywheel. With the pivot and contact points repositioned, these clutches require only a direct compressive force to act on the pressure plate springs. Consequently, there is no need for the release bearing to be attached to the pressure plate fingers.

Instead, the release bearing is integrated into the clutch servo, which directly engages the pressure plate springs. This design eliminates the need for an external pivoting mechanism, thereby removing the requirement for a clutch fork altogether.

The servo mechanism can be actuated hydraulically or pneumatically. In configurations, such as those used in Volvo trucks, a pneumatic clutch control solenoid valve is mounted externally on the gearbox. This valve supplies compressed air to the servo, enabling clutch actuation without mechanical linkages.

Pull type clutch

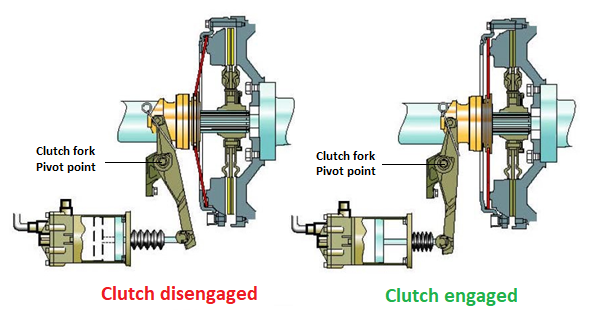

The pull-type clutch includes an additional component: the clutch fork. This fork functions as a pivoting lever that applies a pulling force to the release bearing. When the pressure plate is fastened to the flywheel, its fingers are drawn inward, forming a concave shape. The release bearing is attached to these fingers and moves in unison with them.

One end of the clutch fork fits behind the tabs of the release bearing, while the other end connects to the clutch servo pin. The fork is mounted to the gearbox housing using a bushing and a single bolt, creating a pivot point similar to a seesaw. When the servo pin applies pressure to one end of the fork, the opposite end, positioned behind the release bearing, exerts a pulling force, thereby disengaging the clutch.

When pressure is removed from the servo side, the spring force of the pressure plate draws the release bearing back. Due to the seesaw action of the fork, this movement pushes the servo pin back to its original position.