In these articles, I will be using the motor industry as a reference, but the challenges I’ll discuss are universal across virtually every industry today. In the “good old days,” we were trained to fix, not just replace. We had to understand the problem inside and out, strip it down, figure out how it worked, and repair it if possible. Replacing parts was always a last resort. But today, technicians rely heavily on computers to “diagnose” issues – and often, they end up replacing part after part, hoping the problem will resolve itself, all while passing on skyrocketing costs to the customer.

🧩 The real issue

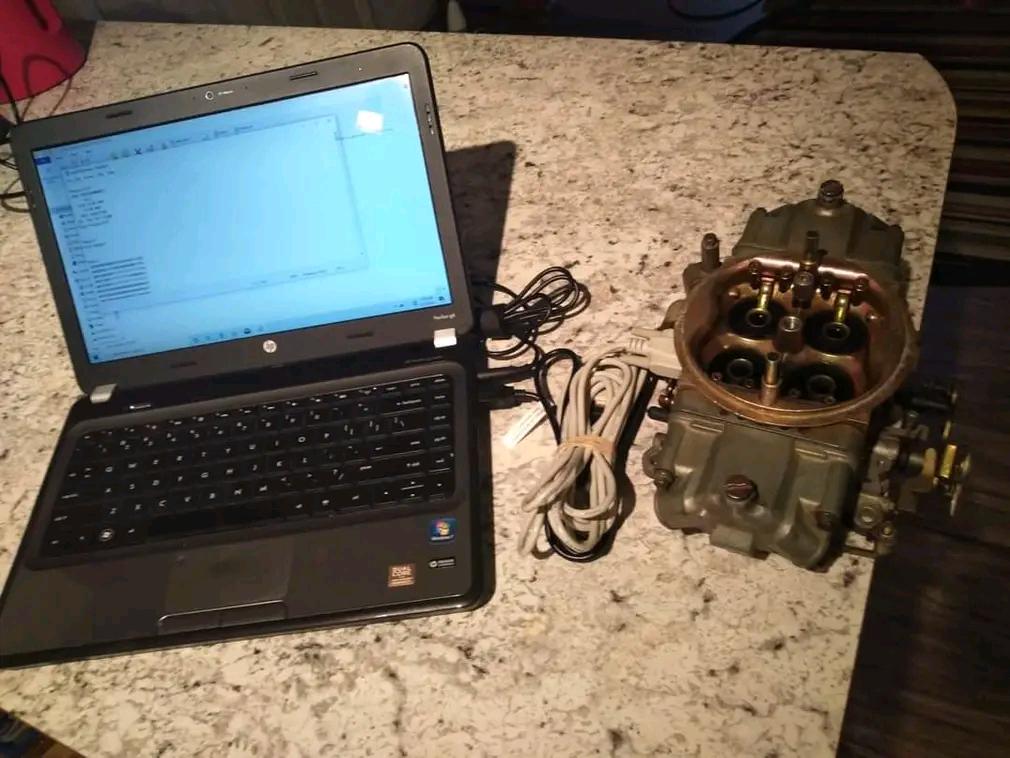

We’ve lost the fundamental understanding of what we’re dealing with. Diagnosing problems isn’t just about plugging in a laptop. The laptop is simply a tool – it doesn’t fix anything on its own. The technician is the one who repairs the fault. Computers and technology should guide us, but they shouldn’t take over the role of a knowledgeable technician.

💡 The beginning matters

Think of knowledge as building materials. It’s all out there, in thousands of pieces. But nothing is built yet, you need to put it together to create a complete building. Sure, you can build the penthouse apartment of a skyscraper building first and hopefully keep it in one piece when lifting it up and placing it in position once the rest of the building is complete. The chances though, is that the walls will crumble and you will need to rebuild the penthouse. Remember, without the foundation and floors below it, the penthouse is just a room at ground level waiting to collapse – it lacks support and structure. Knowledge is the same. You need to assemble it, one piece at a time, filling in the gaps and creating a complete picture along the way.

Too many people today are looking for shortcuts. They want quick fixes, without investing the time and effort to understand the fundamentals. That’s where I stand apart. I believe in starting from the ground up. Understanding the basics is everything. Without that solid foundation, we’re wandering aimlessly.

When it comes to vehicle electrical and electronic systems, understanding means knowing what does what, what communicates with what, how, and when. And that’s not just about electronics – it’s also about mechanical systems. Despite all the advances, today’s vehicles (yes, I’m talking about the traditional ones, not EVs) still operate on the basic principles of the first combustion engine. When you grasp these core concepts, you can start diagnosing with confidence, saving time and money.

Take the Automated Manual Transmission (AMT / Volvo I-Shift) as an example. Many people would simply call it a gearbox that changes gears – and that’s true, in basic terms. But do you truly understand how it works? There’s no clutch pedal or mechanical gear lever. If you don’t grasp the principles behind its operation, diagnosing faults becomes a guessing game. Understanding these systems eliminates the need for constant calls to experts like me – and that’s the power of knowledge.

Starting from the beginning and building a solid understanding is the key to becoming the kind of technician who doesn’t just fix problems, but prevents them.