🎓 The evolution of technology: The more things change, the more they stay the same

In recent years, it’s felt like technology is evolving faster than we can keep up. But if you dig deeper, you’ll realize that today’s advanced technologies are built on ancient ideas. Scientists and engineers are just getting smarter, finding more efficient, compact, and robust ways to improve what’s been around for centuries.

Take the humble wheel and tire, for instance. The Romans had chariots with wheels, but they certainly weren’t running on Michelin Slicks. The wheel itself has been around for centuries, and while tires have evolved to offer better grip and stability, the basic concept remains unchanged, a round object rotating around an axle. Engineers aren’t redesigning the wheel; they’re perfecting it.

We’ve seen similar evolution in engine starting systems. From crank handles to battery-operated starter motors, the goal remains the same, to get the engine rotating fast enough to start and continue under its own momentum. Imagine an investment banker pulling out a crank handle to start his Lambo every day – awkward, right?

And the story’s the same across the board. From clutch cables to hydraulics, accelerator cables to “fly-by-wire,” the goal is the same, to make things move. The methods may have changed, but the outcome remains consistent. Yes, even electric vehicles (EVs) aren’t immune to this logic – they might not have engines, but they still use wheels to get from point A to point B in a more efficient (this is up for debate, innit) way.

The point here is simple, the operation of an engine hasn’t changed much, but how we control and improve it has. Now, let’s zoom in on the trusty 4-stroke engine.

💡 Same concept, smarter execution

At its core, the 4-stroke engine is still the same as it was 50 years ago. Sure, advancements have made it lighter, more efficient, and turbocharged, but the basic idea remains unchanged. Back in the day, popping the hood would reveal a massive chunk of cast iron with a few wires and cables, while today it’s a neat plastic cover hiding a web of wiring harnesses and electronic components. I remember the first time I saw the engine bay of an Audi A4 Tiptronic Quattro. I asked my dad, “How do you work on that?” and he simply replied, “You don’t, you take it to the dealer, even to fill the coolant!” Classic.

But I get it—modern engines can seem like a confusing mess. That’s where I come in! I’ll help you settle your nerves and get you on the diagnostic path to engine happiness.

💪🏻 So, What’s the big deal?

At the end of the day, an engine is an engine. Whether it’s a Lamborghini, a Mercedes, or a Fiat, the fundamental principles are the same: pistons move up and down, fuel and air are drawn in through valves, and explosions drive the 4-stroke cycle. What differs is the design, layout, and controls. But no matter the brand, the goal is the same, make an engine run.

🧱 Let’s break it down: The 4-stroke petrol engine

In the “good old days,” we had accelerator cables connected to carburetors. You pressed the accelerator, the cable pulled open a butterfly valve in the carburetor, allowing air to flow through, creating a vacuum that sucked in fuel to mix with the air. This mixture was then delivered to the engine, sparking the power stroke. (Yes, critics, there was also a mechanical pump involved!)

Today, things are a little more sophisticated. We’ve replaced carburetors with throttle bodies, airflow meters, fuel injectors, and an array of sensors, all controlled by an Engine Electronic Control Unit (EECU or EMS – Engine Management System). These components work together to deliver the perfect air/fuel mixture, precisely timed for optimal performance.

💥 From distributors to coil packs: Ignition systems evolved

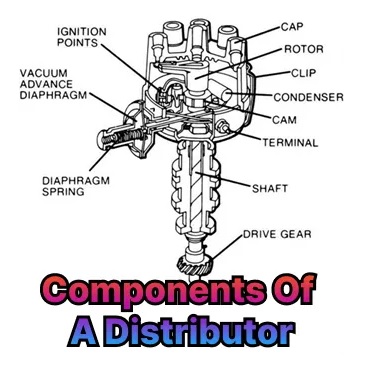

Back in the day, engines used distributors, complete with a rotating shaft, points, a condenser, a coil, and high-tension leads. When the engine was running, the distributor would send the right amount of current to the spark plugs. It was a manual system, and timing had to be adjusted using a timing light, ensuring the spark occurred just before Top Dead Center (TDC).

Fast forward to today, and we have coil packs directly connected to each spark plug. The result? A spark at the exact right moment to ignite the fuel/air mixture – no timing light necessary.

⚒ Mechanical vs. modern: How the systems work

In the past, fuel was drawn into the engine purely by the vacuum created by the piston’s downward movement. The distributor would control the timing, and fuel intake was metered by jets and venturis, with a constant vacuum feeding fuel into the engine. By changing jet sizes and adjusting screws you could tune the engine to run rich (too much fuel), lean (too little fuel) or somewhere in the middle (just right). This was also at a time when we had leaded fuel and taking a quick squiz at the colour of the exhaust could tell you everything you needed to know about how your engine was running (black – too rich, white – too lean and grey – just right).

Modern engines have swapped mechanical systems for electronics, making everything more precise and efficient. The Engine Management System (EMS) uses sensors to monitor engine performance, adjust fuel injection, control ignition timing, and optimize throttle response. Everything happens with pinpoint accuracy, improving efficiency, performance, and emissions.

🚀 The future: Small, smart, and efficient

As technology advances, electronic systems are getting more precise. Modern ECUs can predict conditions and adjust the engine’s performance automatically, without the driver needing to lift a finger. It’s all part of the same evolutionary process – refining what already works rather than reinventing the wheel.

And while it may seem like modern engines have a lot more components than their predecessors, the truth is that these components are smaller, lighter, and far more precise. The result? Better performance, better fuel efficiency, and reduced emissions – something we can all feel good about.

📦 Conclusion: Evolving, not revolutionizing

So, while the technology behind modern engines has evolved dramatically, the basic principles haven’t changed. The goal is still the same: to get those centuries-old round wheels turning in the most efficient way possible. And as we continue to refine and optimize these systems, the result is an ever-smarter, more efficient machine – no crank handles required.